GYTA53 Fiber Optic Cable |

|||||||

|

|||||||

| Details : | |||||||

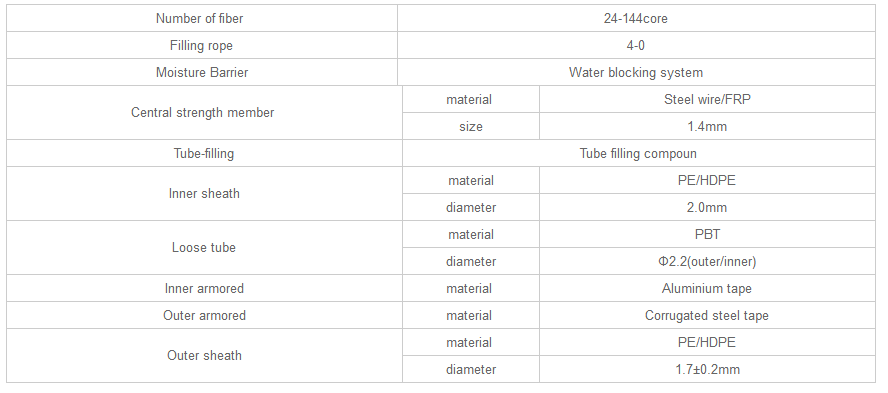

The fibers, are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water-resistant filling compound. A steel wire, sometimes sheathed with polyethylene (PE) for cable with high fiber count, locates in the center of core as a metallic strength member. Tubes (and fillers) are stranded around the strength member into a compact and circular cable core. The cable core is filled with the filling compound to protect it from water ingress, over which a thin PE inner sheath is applied. After the PSP is longitudinally applied over the inner sheath, the cable is completed with a PE outer sheath. Characteristics: · Good mechanical and temperature performance · High strength loose tube that is hydrolysis resistant · Special tube filling compound ensure a critical protection of fiber · Crush resistance and flexibility · The following measures are taken to ensure the cable watertight: · Steel wire used as the central strength member · Loose tube filling compound and 100% cable core filling · APL moisture barrier · PSP enhancing moisture-proof · Water-blocking material Technical Parameters:  |

| Related Products : |